OVERVIEW

Timeline: September - December 2016 (3 months)

Focus: Precision machining | Design for Manufacturability | Engineering

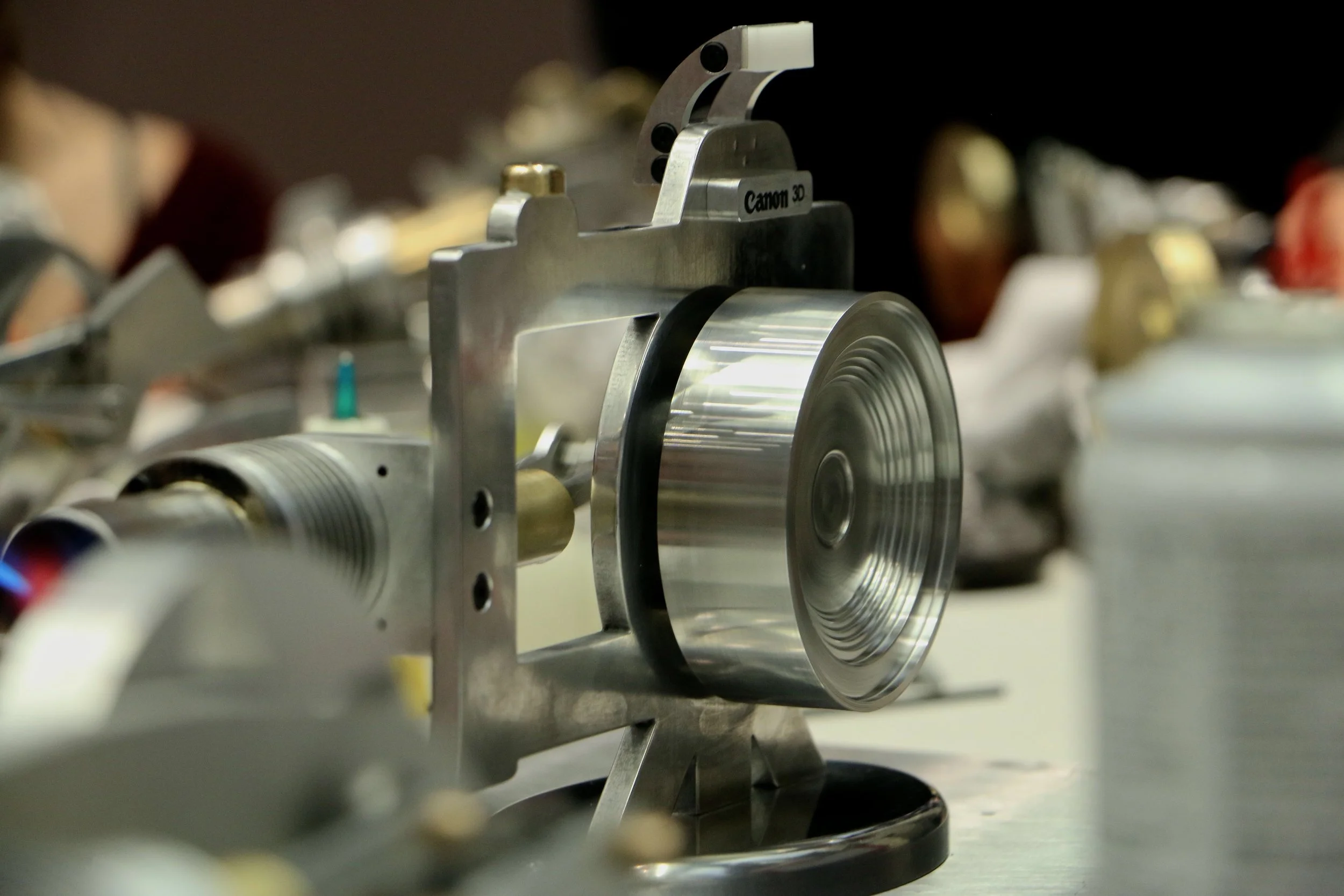

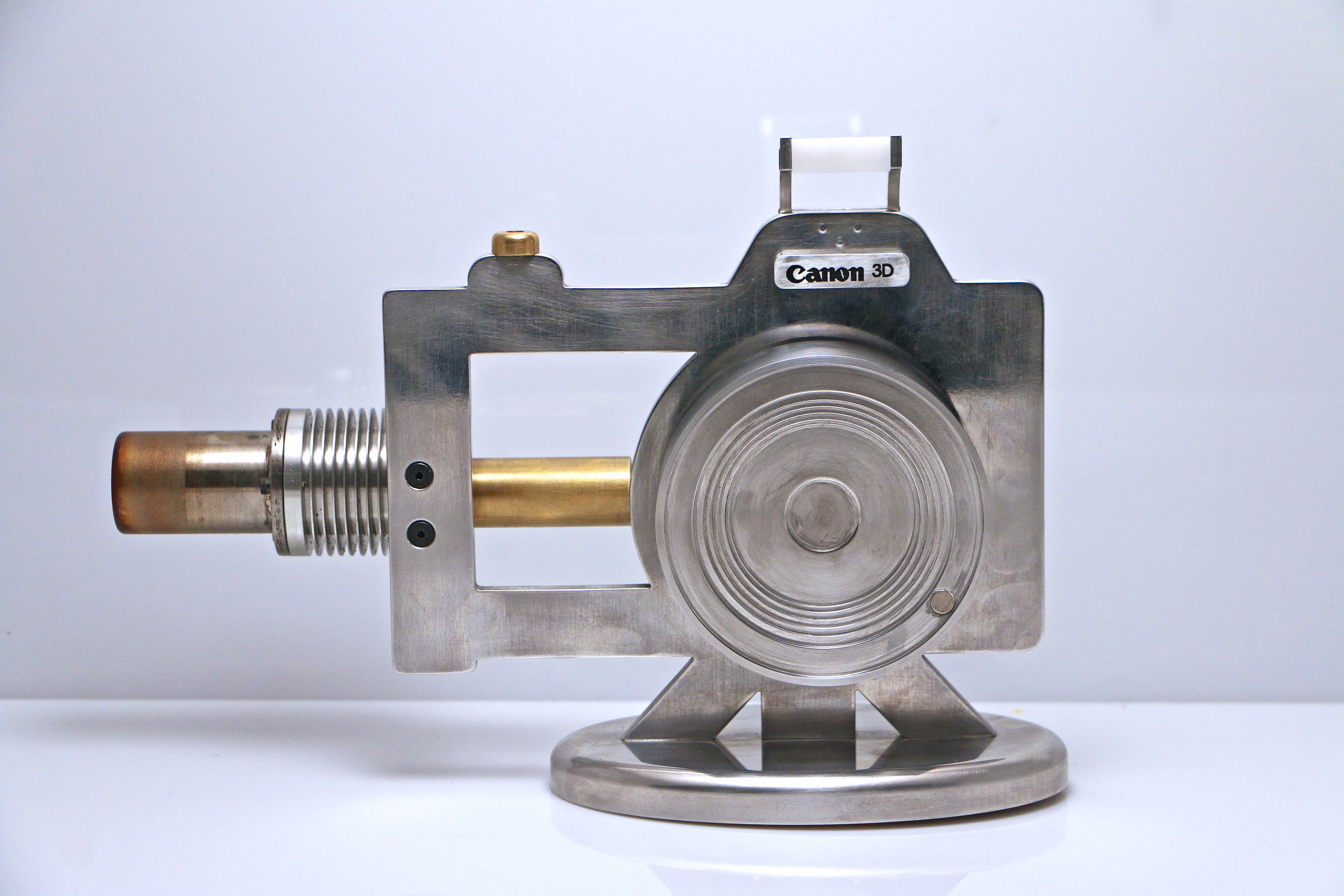

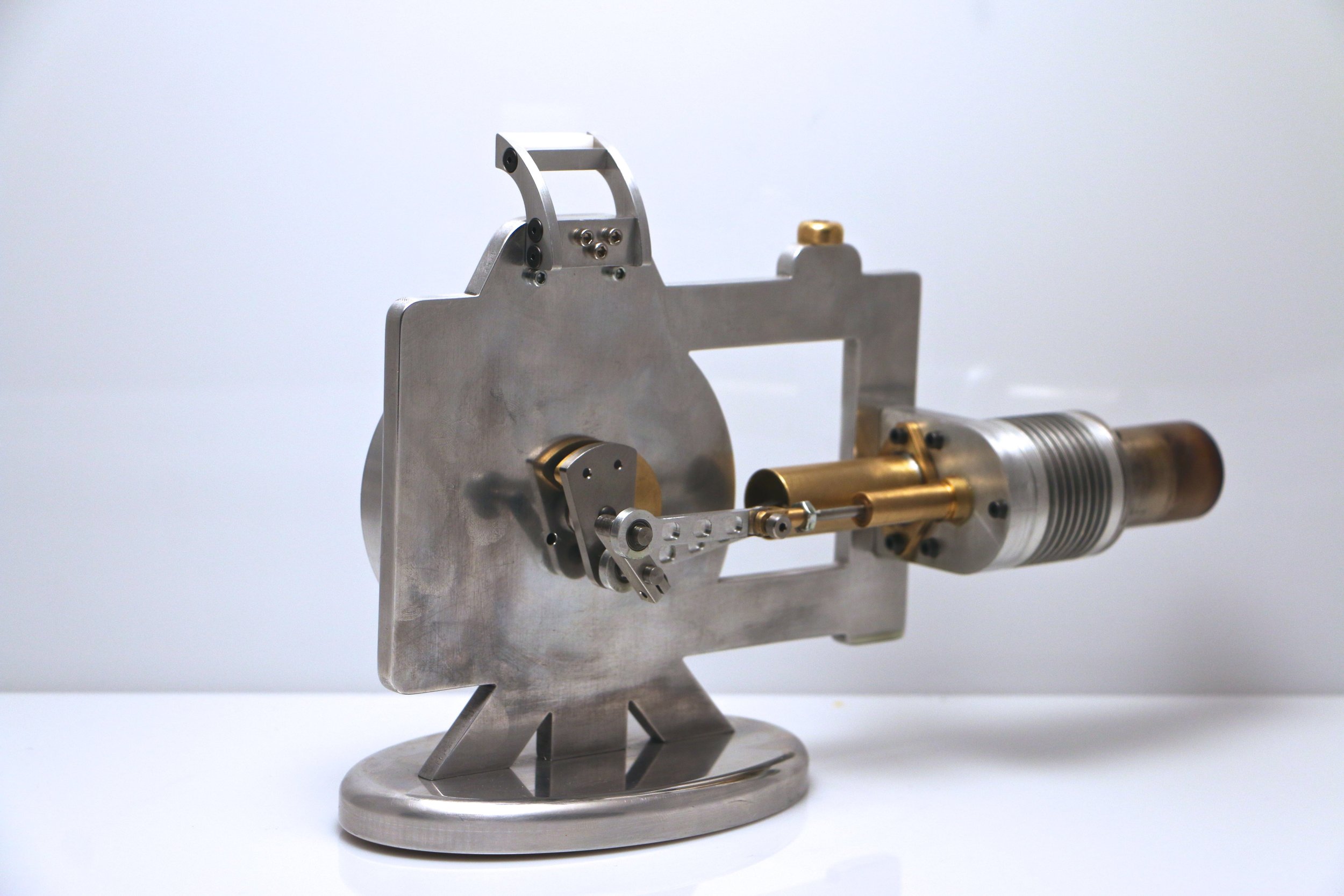

I designed and fabricated a fully functioning Gamma type Stirling engine, which operates converting heat energy into mechanical work. This technical-oriented project introduced me to important technical aspects of engineering design including tolerances, engineering drawings, and various manufacturing methods and tradeoffs. Inspired by my love of photography, I designed a camera-themed engine, with a lens as the flywheel. I modeled the engine on SolidWorks and created a functional virtual assembly. This process helped me to visually understand the mechanisms of the engine and how the components interface before fabrication and assembly. My engine ultimately ran at a speed of 635 rpm during testing.

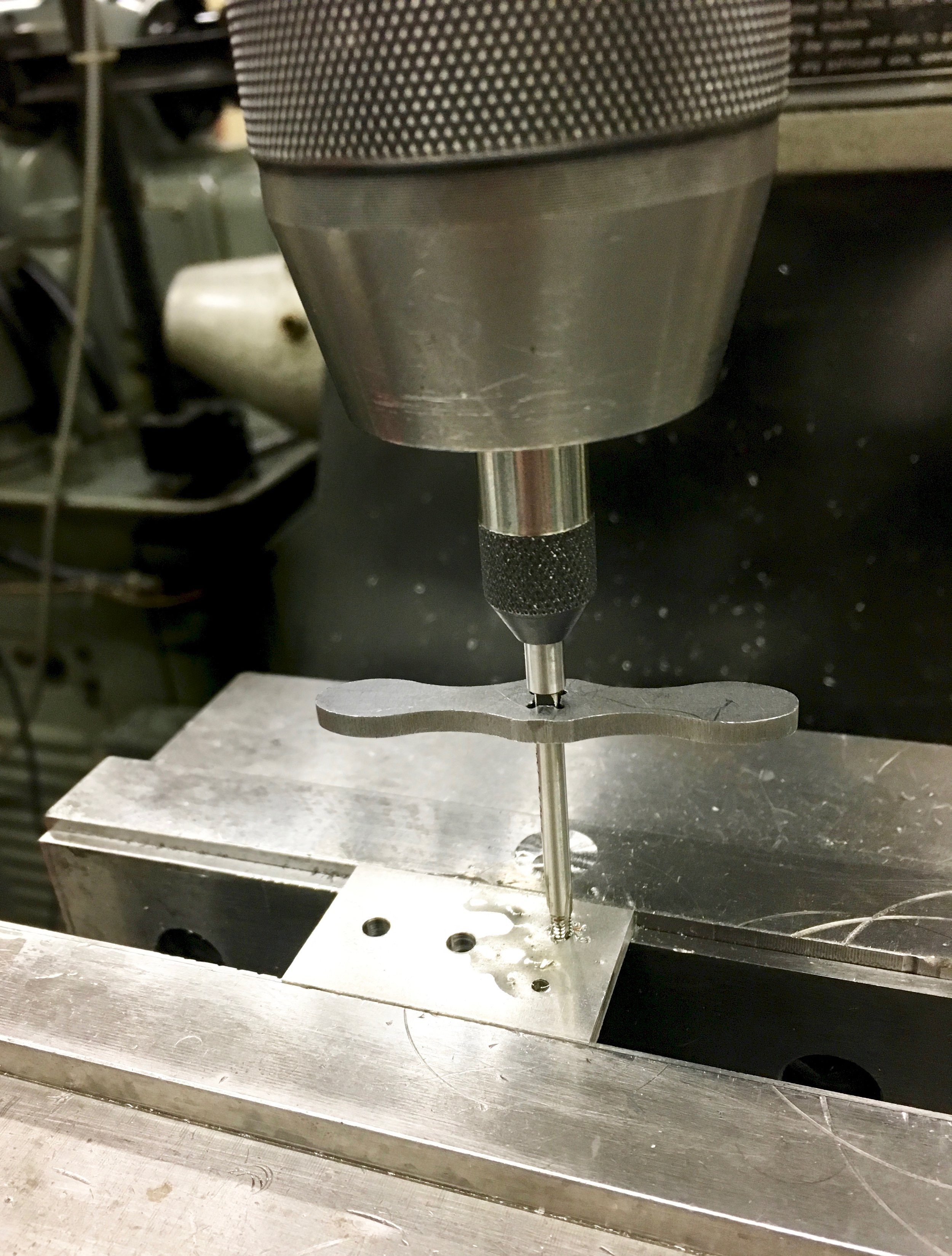

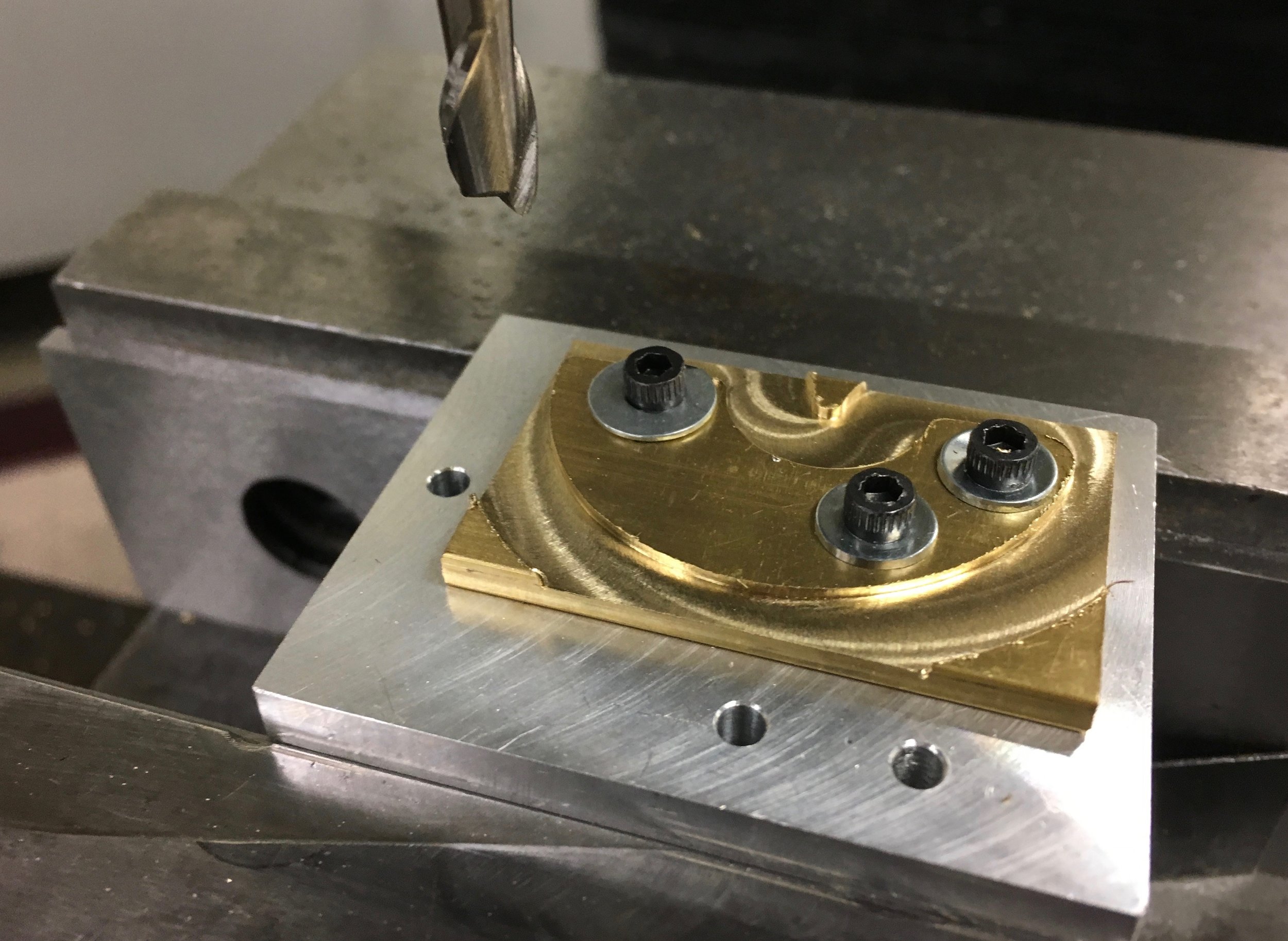

MACHINING PROCESSES

We were provided with engineering drawings for 8 fully defined parts to fabricate. Additionally, we were challenged to design and fabricate 7 engine parts based on only a few guiding parameters to ensure assembly. I machined the engine components on CNC mills and lathes, using a variety of materials including aluminum, brass, and stainless steel.